OIL AND GAS

Providing complete rig designs including ancillary equipment and buildings. From tele-doubles on step down substructures to hydraulically raised triples on swing up substructures, we have experience designing and providing excellent fabrication drawings.

ENGINEERING CONSULTING

From API consulting services that include design binders and third party design reviews to CWB retained welding engineer and welding procedures, we have a wide range of experience. We also have extensive experience with structural finite element analysis using both linear, and non-linear analysis, as well as using hybrid models making use of beam and shell elements to provide additional insight into how a structure behaves. We also perform failure analysis, as well as accident investigations and fire and explosion investigations.

SPECIAL SERVICES

Some additional special services that we provide include equipment ratings and design reviews of specialized trailers. We also design various pieces of lifting equipment and spreader bars, and perform lift studies including animations of the actual lift to ensure proper range of movement and verification of operating envelopes.

SHOP / FIELD / OPERATIONS SUPPORT

We provide engineering support for shop operations, calculating ratings for custom fabricated equipment, stands, and lifting devices. If no operating manuals or instructions are available, we can assist in creating the necessary documents to meet Occupational Health and Safety requirements. We also provide field support in examining and determining the extent of damage from an incident, and providing repair procedures, including welding procedures, and following up with a repair certification. For operations, sometimes there is a need to move equipment or make modifications to existing structures, and we can help with those procedures and provide the required paperwork.

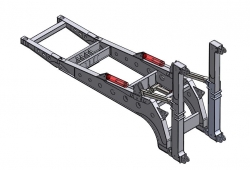

750 kip DRILLING RIG WITH MOVE SYSTEM

DAIR designed a 750 kip stiff double, box on box substructure with move system designed for either straddling or spanning a cellar.

DRILLING RIG CONCEALMENT

ENSIGN Drilling approached DAIR for the design of a concealment package to be designed into the design of their 750 kip stiff double. The concealment was required to make the drilling rig look like a building, to blend into the urban setting.

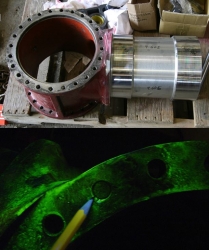

DAMAGE ASSESSMENT

DAIR has performed damage assessments on incidents where the block impacted the crown, crown damage during transport, and damage on a torque tube and a top drive.

CRANE DAMAGE ASSESSMENT AND REBUILD

DAIR was approached by the owner of a 1966 Link-belt crane to see if a damaged component could be repaired or rebuilt.

DAIR worked with a fabrication shop to build a replacement assembly so the crane could be quickly put back into service.

REPAIR PROCEDURES ON A COMPONENT OF A SURFACE HOLE RIG

DAIR was approached by a local fabrication shop that had been hired to perform repairs on a cast part on a rig.

DAIR worked with the fabricator to take metallurgical samples so that a weld procedure could be developed.

DESIGN OF CRANE BOOM DOLLEY

A local crane company needed a unique design for a crane boom dolly that allowed for storage of the crane's counterweights. A design requirement was to still allow easy access during rig-up.

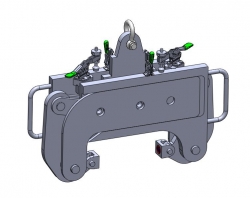

MISCELLANEOUS LIFTING DEVICES

DAIR designed a number of adjustable lifting devices for handling a range of valve bodies in a production environment.

DESIGN REVIEW OF HEAVY HAUL TRAILER

DAIR performed a Design Review of a heavy haul trailer with a capacity of 300,000 lbs.to be used in the transportation of transformers as well as large vessels. The project brought vessels from Lewiston, Washington to Grande Prairie, Alberta.

DESIGN REVIEW OF TRAILERIZED SUBSTRUCTURE

A Design Review was performed and an API Design Binder was prepared for a company pursuing API Certification for their fabrication shop.

MISCELLANEOUS EQUIPMENT CERTIFICATION

DAIR worked on a number of projects providing ratings for lugs and equipment, such as cranes and trolleys, support booms, walkways, and doghouse raising systems.

Who is DAIR Engineering Inc.

The principals of DAIR Engineering are Senior Mechanical Engineers that have been working in various industries from:

- Consulting Engineering

- Manufacturing of Oil Rigs and Associated Equipment

- Structural Steel Building and Connection Design

- Welding Joint Design and Welding Procedures

- Design of a Laser-cutter for the Textile Industry

- Research and Development of a Consumer Computer Mass Storage Device

- Fire and Explosion Investigations

- Failure Analysis

- Fatality Investigations

In addition to the technical aspects of engineering, they have also been involved at different management levels within larger companies. This includes the management of both technical and non-technical personnel. Additionally, they have had experience running their own companies.

The result of this combined experience is a vast background of knowledge spanning many different industries, resulting in keen problem-solving and analytical skills.

This experience is reinforced with experience on many different software applications such as Computer Aided Design and Drafting, Finite Element Analysis, Structural Analysis, as well as the traditional Microsoft Office applications.

We enjoy challenges requiring out-of-the-box thinking, and are interested in discussing how we might be able to help you.

| |

PROFESSIONAL MEMBERSHIPS

DAIR Engineering Principal

Barton F Pawluski, P.Eng C.F.E.I.

Barton is a Senior Mechanical Engineer with experience in Research and Development as well as Production environments. Hands-on practical experience provides technical solutions to problems that can be fabricated. Extensive experience with CADD and Engineering Analysis software ensures that potential design flaws and weak spots are avoided. Barton enjoys applying traditional engineering to non-traditional applications to help clients find solutions to their problems. Fire Investigations and Failure Analysis are also an area that Barton has worked in, providing reports that describe technical issues in a way that non-technical readers and understand and follow. Although Barton may not have experience in the exact field that you are working, he has successfully worked in a wide range of industries. The key to success is in working with you to understand your business, your product line, and your challenges, and then working together with you to find an appropriate engineered solution.

Growing up with a weekend grain farm exposed Barton to machinery where he learnt to both operate and repair them.

During high school Barton was in Air Cadets, where he earned Top First Year Cadet, a Glider Pilot Scholarship and a Private Pilot Scholarship. The summer after graduating high school, Barton got his pilots license.

Before graduating from Mechanical Engineering at the University of Alberta, Barton had the opportunity to work for a number of interesting companies, one was designing and manufacturing an ultralight, the Golden Hawk where he worked as a draftsman.

https://en.wikipedia.org/wiki/Falconar_Golden_Hawk

https://en.wikipedia.org/wiki/Falconar_Golden_Hawk

Another company was designing and building a laser-cutter for the textiles industry, where he worked as a CAD Operator / Mechanical Technologist. He worked on the superstructure, the main conveyor and the auxiliary conveyor, the x-y positioner and components of the laser beam delivery system. It was in designing the flying mirror mount of the beam delivery system that it became apparent to Barton that he needed to get a Mechanical Engineering Degree.

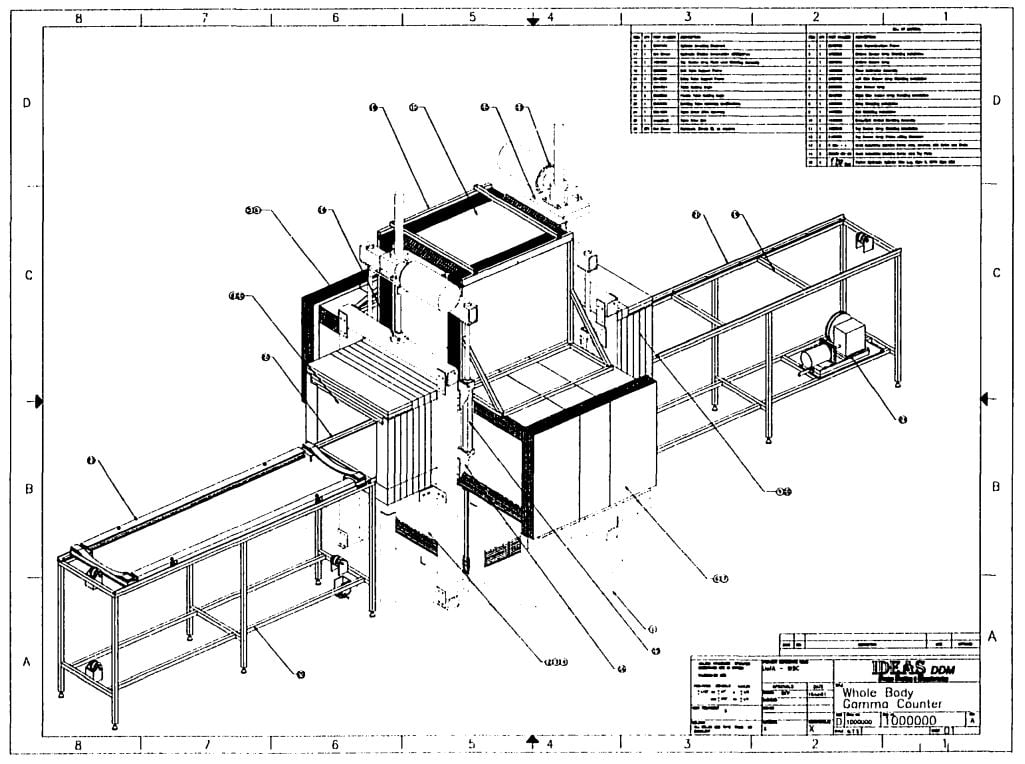

While attending University, Barton worked with a physics student that was working on his doctoral thesis, developing a Whole Body Counter to detect the location of cancer in patients. A cancer patient would be given a radioactive injection, and the radioactive material would be absorbed by the cancer cells. The patient would then be scanned in the Whole Body Counter to detect the location of the radiation, and thus the location of the cancer.

https://ieeexplore.ieee.org/document/900744

https://ieeexplore.ieee.org/document/900744

After graduation Barton went to work for a local fabrication company that had just purchased a Crane Manufacturer from Eastern Canada, and was moving its operations to Edmonton. Here Barton was helping in getting the Crane department set-up, as well as filling customer's orders.

https://weldco-beales.com/products/hydra-lift-cranes/

https://weldco-beales.com/products/hydra-lift-cranes/

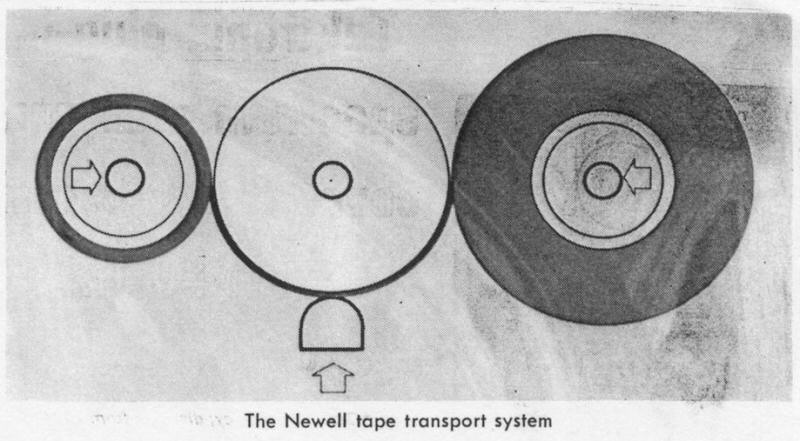

Not long after that, based on his experience in research and development Barton was hired as the Mechanical Engineering Manager for a small Research and Development company that was developing a computer mass storage unit using an Optical Tape Cartridge. The cartridge was capable of storing large amounts of data, while also having very fast access times and transfer rates. The President of the company, Mr. Ches Newell had many patents and was looking to prepare Mass Storage Systems for companies like NASA, Compaq, and Disney. Unfortunately before the project was completed Mr. Newell passed away.

Here is some background information on Mr. Ches Newell and the Opticel project.

http://www.labguysworld.com/ChesterNewell.htm

http://www.labguysworld.com/ChesterNewell.htm

http://www.labguysworld.com/ChesterNewell_2.htm

http://www.labguysworld.com/ChesterNewell_2.htm

http://www.labguysworld.com/ChesterNewell_3.htm

http://www.labguysworld.com/ChesterNewell_3.htm

https://ntrs.nasa.gov/citations/19950017699

https://ntrs.nasa.gov/citations/19950017699

Barton then went to work for Farr Canada, and Edmonton company that built hydraulic power tongs for the Oil and Gas industry. His first design task was to develop a scissor lift that would operate between well center and the mousehole of a drill ship, and could carry either a 14" tong and back-up or a 20" tong and back-up.

www.youtube.com/watch(2:46)

Eventually Barton was involved with designing a 14"-130,000 ft-lb continuous tong, back-up and scissor lift for interference thread drill pipe.

https://youtu.be/diX3XTz_12U?t=163

https://youtu.be/diX3XTz_12U?t=163

He then moved on to work for a company that provided Mobile Contract Dewatering Services across Canada and the United States to Water, Wastewater, and the Pulp and Paper Industries. Large bowl diameter centrifuges, custom designed screening equipment, screwless conveyors and dredges were the main pieces of equipment, with trash pumps, and progressive cavity pumps being some of the ancillary equipment. He worked on designing specialized equipment, improving process performance, reducing maintenance, and developing an equipment utilization program linked to the periodic preventative maintenance program. Additionally, specialized projects required new equipment and new equipment configurations to meet both site and process needs. This project required a drainage canal to be dredged to remove sediment, and return the water back to the canal without increasing turbidity. A project constraint was to have all of the process equipment located on a small area of land located between the drainage canal and the owners properties. This website has pictures of the configuration of the process equipment.

http://shorelinefoundation.com/jobs/sunset-park-canal

Another project required dredging of the Hylebos Waterway in Tacoma, Washington. Again specialized equipment was designed and built to meet the very tight project requirements of the chemical treatment process. Barton was part of the Trimax team that dealt with some initial contract issues that were encountered during start-up.

It was during this time that he became comfortable in a production fabrication setting where clear concise drawings and assemblies eliminated mistakes and minimized re-work which is critical to a production company's success. This was possible because the original engineering design took into consideration the different fabrication processes that were going to be used to fabricate the parts, and which processes were best suited for each part. Dimensioning and tolerancing on the drawings would then be tailored for each fabrication process.

Barton them went on to Allan Nelson Engineering and worked as a Senior Mechanical Engineer, and Engineering Manager. Here Barton worked on Equipment Designs and Certification, Level IV Inspections, Damage Assessments with Repair Procedures and Repair Certifications, Failure Analysis, Fatality Investigations and Fire Investigations.

Here are some of the many projects that Barton worked on:

Commercial Kitchen Fire Investigation

Dual Fatality Investigation

Plastics Processing Plant Equipment Replacement Costing

http:/www.albertalocalnews.com/news/Recycling_facility_burns_in_Red_Deer_43271957.html?mobile=true

Modular Home Manufacturing Plant Custom Equipment Replacement Costing

http:/journalofcommerce.com/Home/News/2007/10/Massive-blaze-destroys-factory-of-pre-manufactured-home-builder-Triple-M-JOC024926W/

Fire Investigations

Kenworth Truck Fire - complete loss

Forestry Mulcher Fire Investigations

Doghouse Fire Investigations

Pump Jack Fire Investigation

Fire Investigation of Hotsy

Fire Investigation at Tank Farm with 1000 gal Propane Tanks

Damage assessment of Picker Crane after turret fire, repairs and re-certification

Service Rig Roll-Over Damage Assessment

Service Rig Mast Raising Damage Assessment

Mast Failure Investigation

Service Rig Mast Failure - Mast Replacement

Inspection, Certification and Determination of Remaining Life of Portal Crane

http:/www.youtube.com/watch?v=FdVn0CZsgVA

Freestanding Conversion of Service Rigs

Centrifuge Drop Damage Assessment for Insurance

Fibre Reinforced Plastic Pipe Failure Investigation

Investigation into vessel that sagged during post weld heat treating process

Design of interchangeable moving system for Swing-up Substructure or Box on Box Substructure

Determination of Failure of Fifth Wheel

Crane Slewing Bearing Bolt Failure Investigation

Failure Analysis on a set of Forklift Forks

Dewatering Skid Design

Damage Assessment and Documentation of Pipe Bender

Replacement portal crane trolley design

Inspection of Bucketwheel in Form McMurray Discovery Center

We have extensive experience with equipment upgrades and modifications in both machining and fabrication, which translates into upgrades that can be easily incorporated into existing designs.

We can measure and analyze the equipment to determine what has to be reinforced or replaced to meet Code requirements. We will provide a concise and complete set of fabrication and installation drawings.

We will perform an inspection of the modifications and issue a certification for the equipment at the upgraded capacity.

With backgrounds ranging from textiles lasercutters to ultralights to computer mass storage devices, we have a wide background of problem solving.

If you have had a challenge that you have not yet overcome and need some assistance, we may be able to help.

Please contact us so that we can find out more about your company and how we can help you.

Worked with a client to test, analyze and verify proprietary lifting device capacities.

Performed an investigation to determine cause of water damage in a motel.

Worked with a client and another Engineering Firm on a R&D; Project developing a proprietary vertical conveyance system.

Guardrail and handrail design for Queen Elizabeth Park road.

Design and Finite Element Analysis support of a customized trailer for lifting dragline bucket.

Working with a client to further refine their composite panel shoring system.

DESIGN

![]()

Service Rig Design

Drilling Rig Design

Lifting Equipment Design

Equipment Design

ANALYZE

![]()

Finite Element Analysis

Structural Analysis

Insurance Billing Analysis

INVESTIGATE

![]()

Failure Investigation

Fire & Explosion Investigation

Accident Investigation

REPORT

![]()

Clear

Concise

Detailed